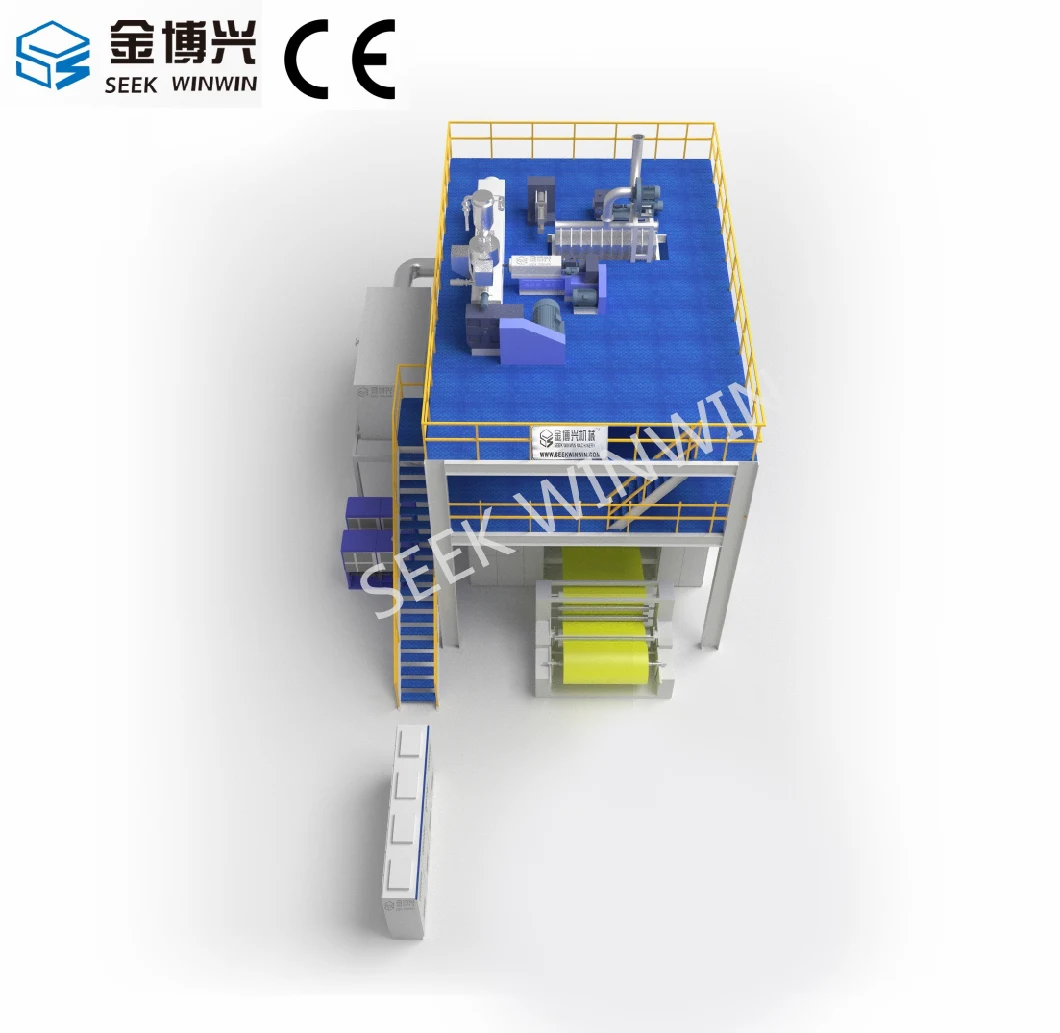

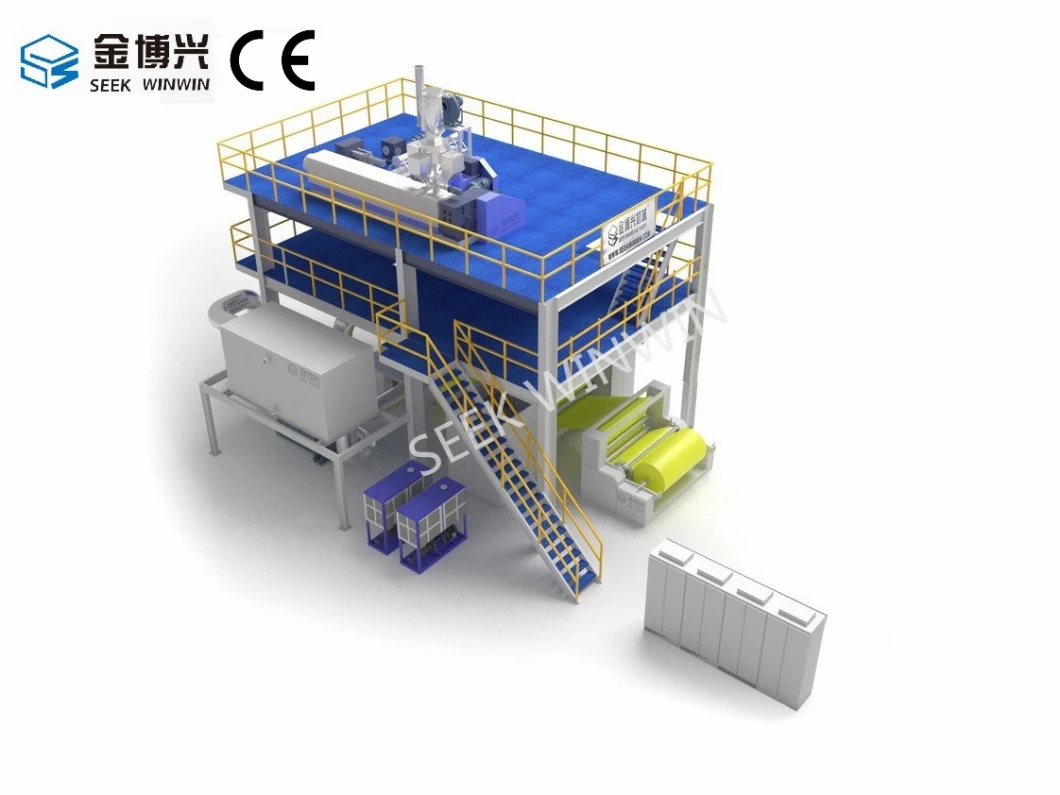

PP Spunbond Non Woven Machine Non-woven Fabric Produce Line

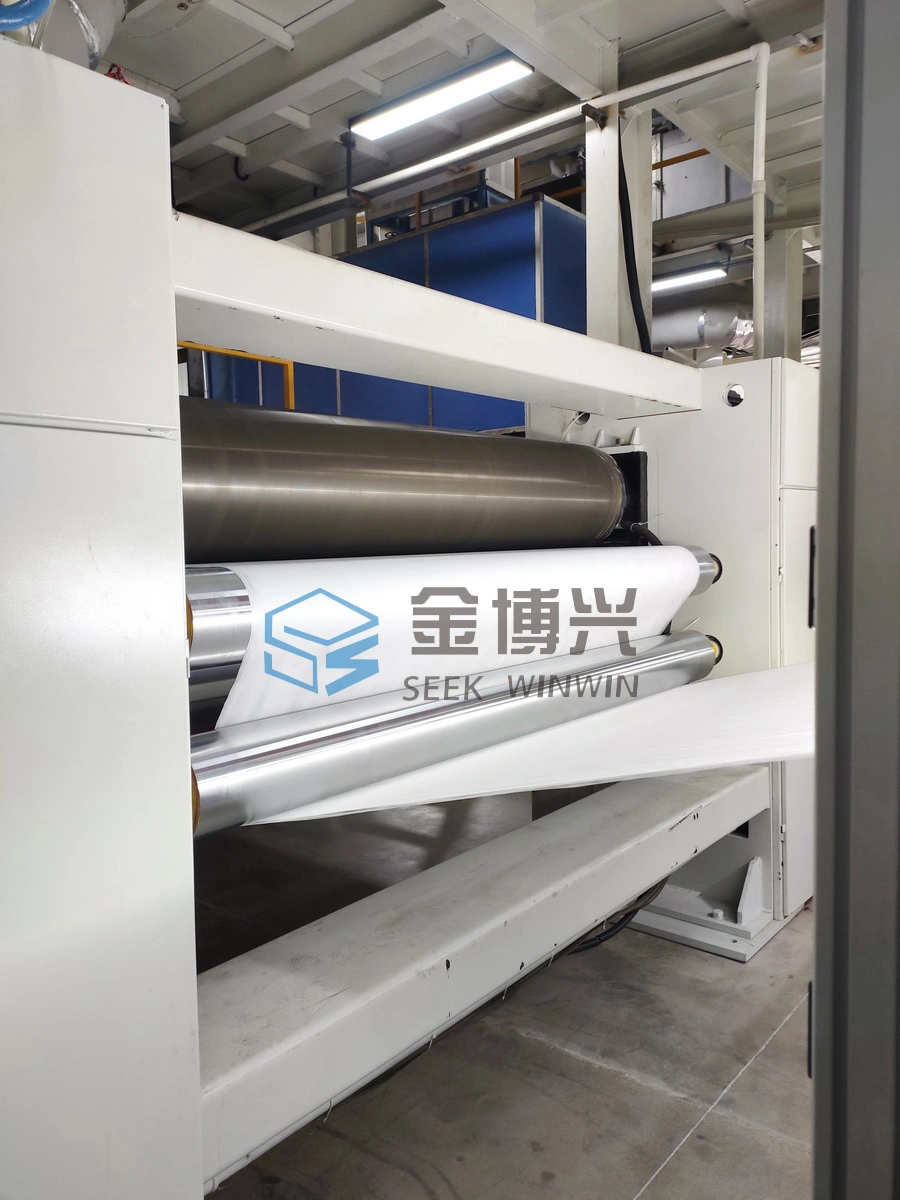

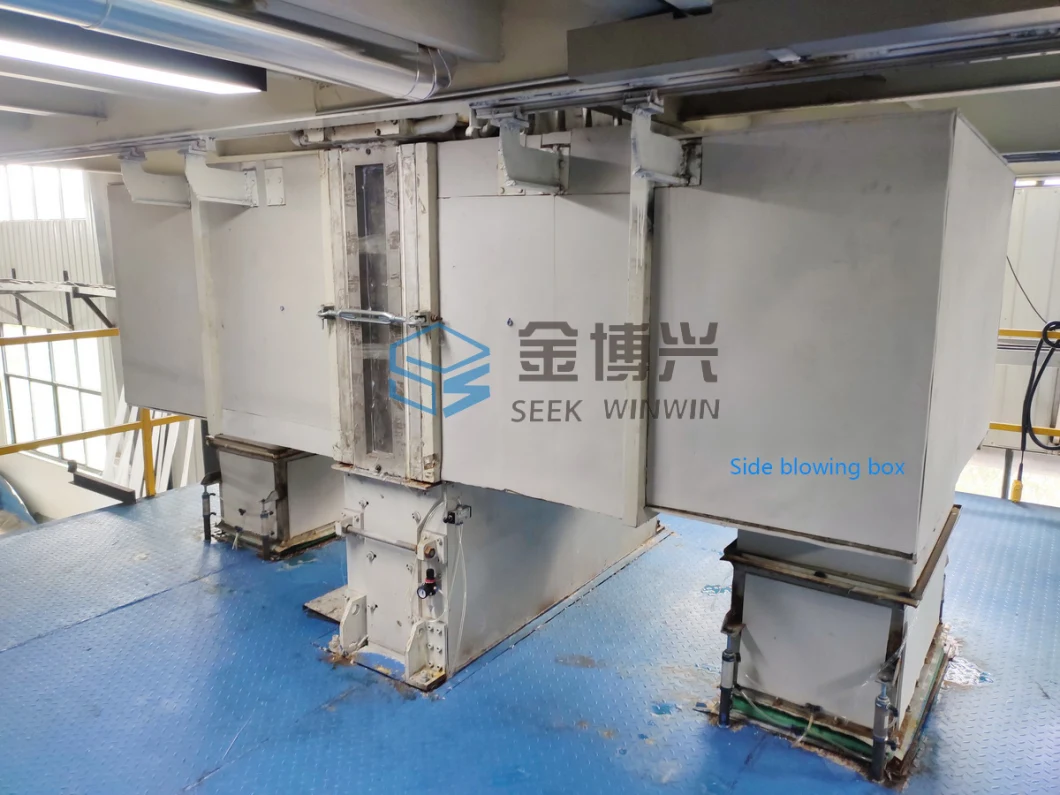

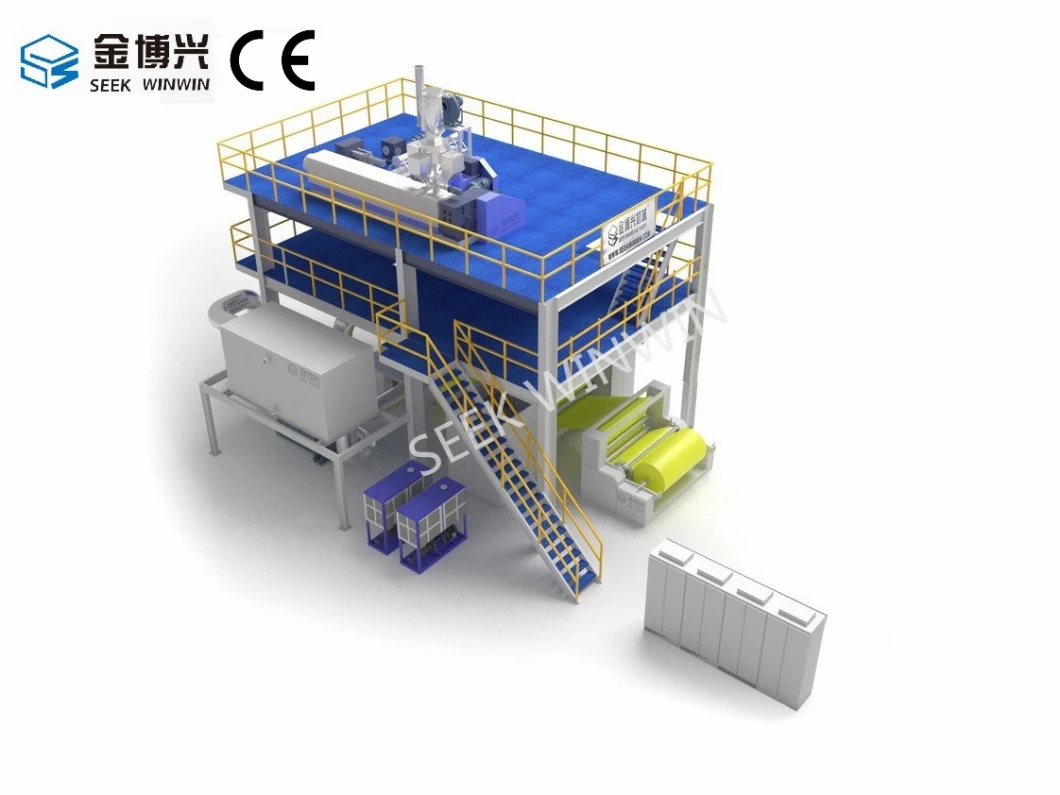

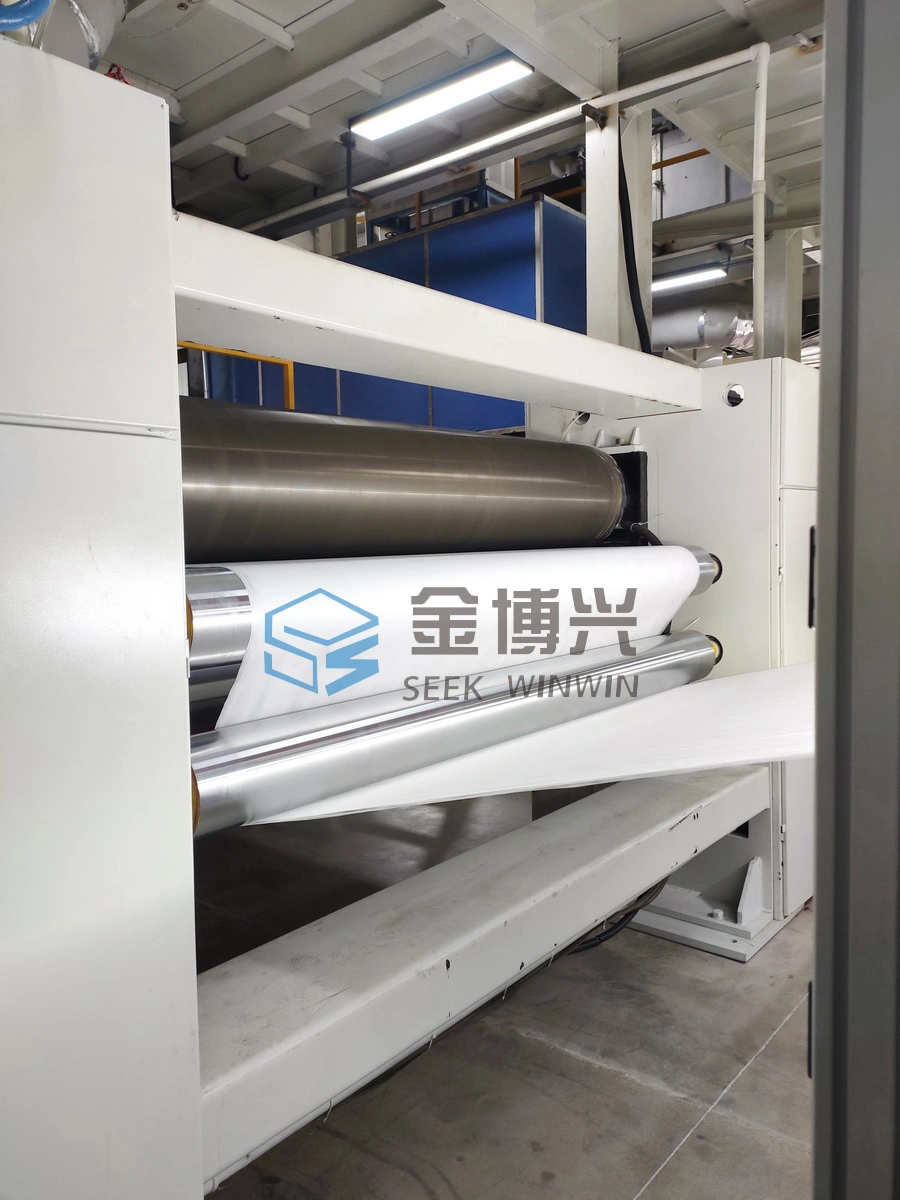

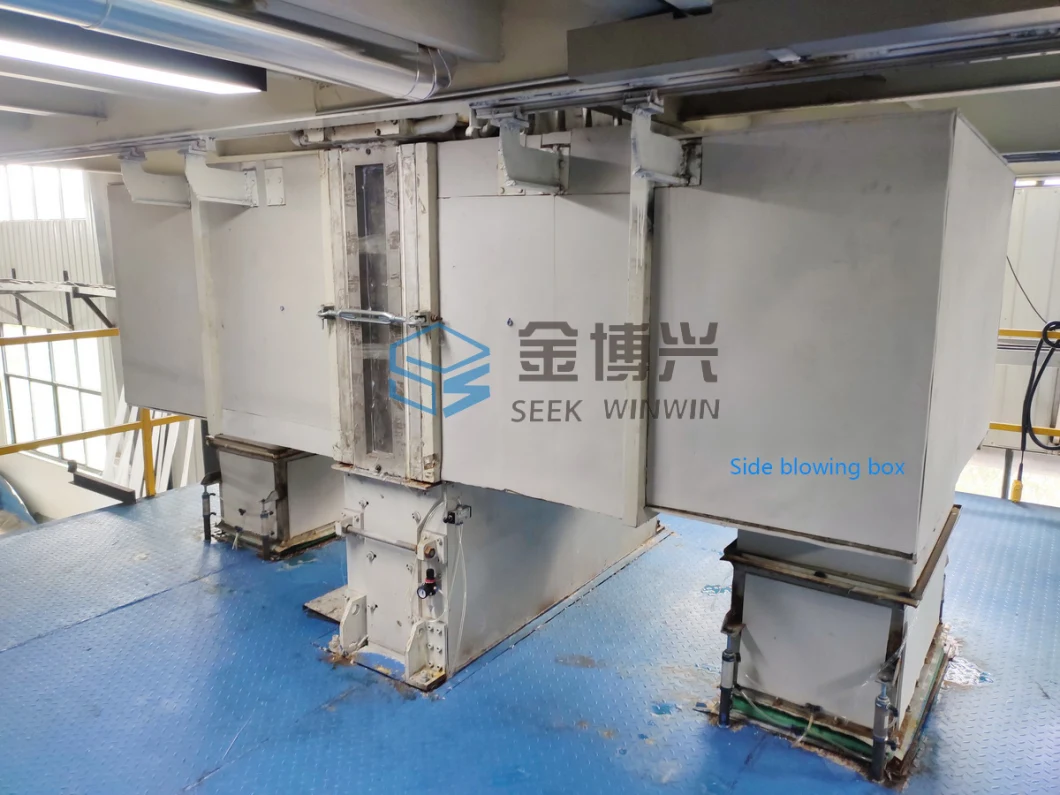

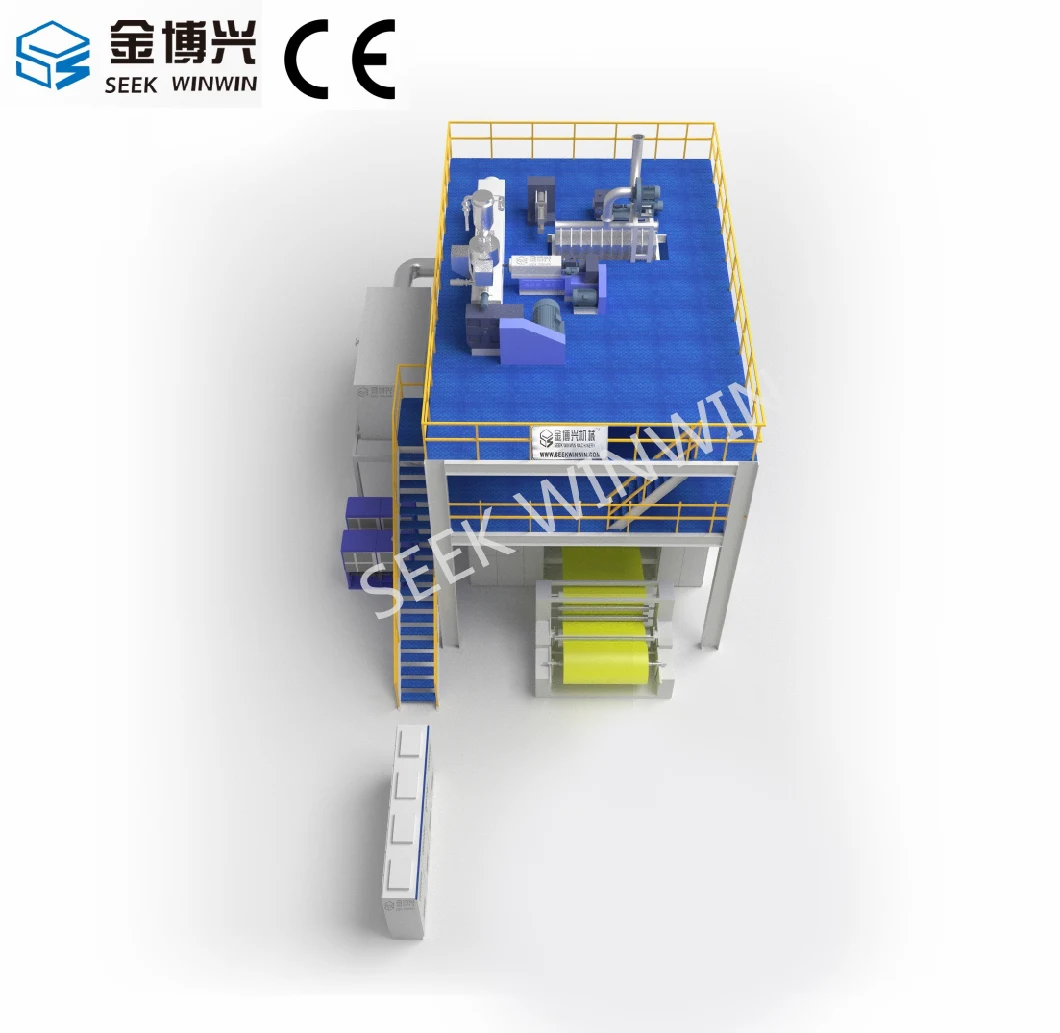

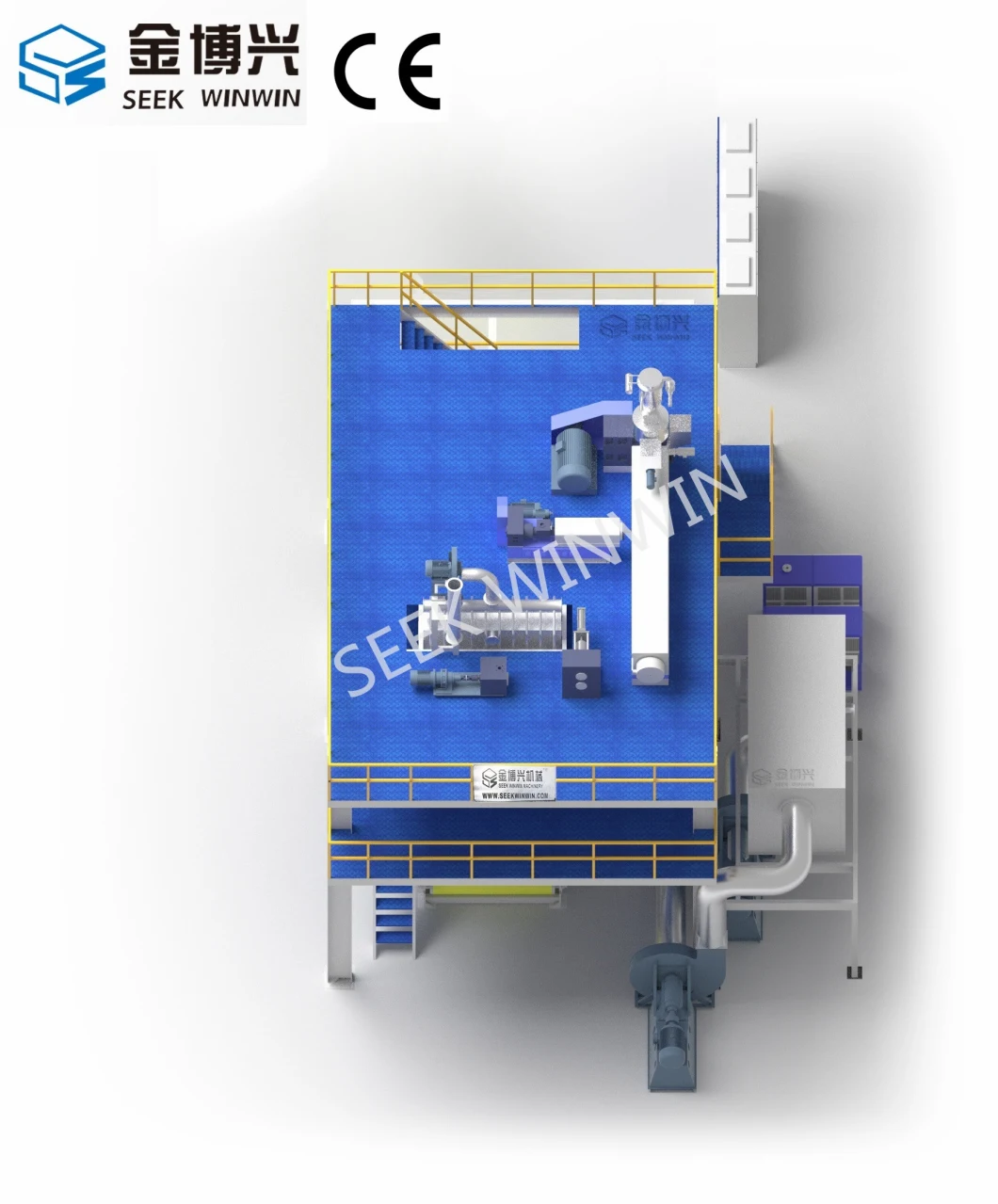

The line is to use PP chips as raw materials input, undergoes the Process of extrusion, spinning, quenching, closure air stretching, web Formation, calendering, winding and cutting as per requirements and Then packed for storage and delivery.

1)The lower investment can reduce some unnecessary additional auxiliary facilities, and under the conditions of guaranteeing the technology requirement and safe production, can reduce the cost of the manufacture, so that we can reduce the investment lower.

2)It is easy and reliable to making technics adjustment, the line adopts the method of computer controlling assistant systems combines with human control to make the technics adjustment become more easier and reliable, and the machine can adapt to different raw materials to gain more widely usage.

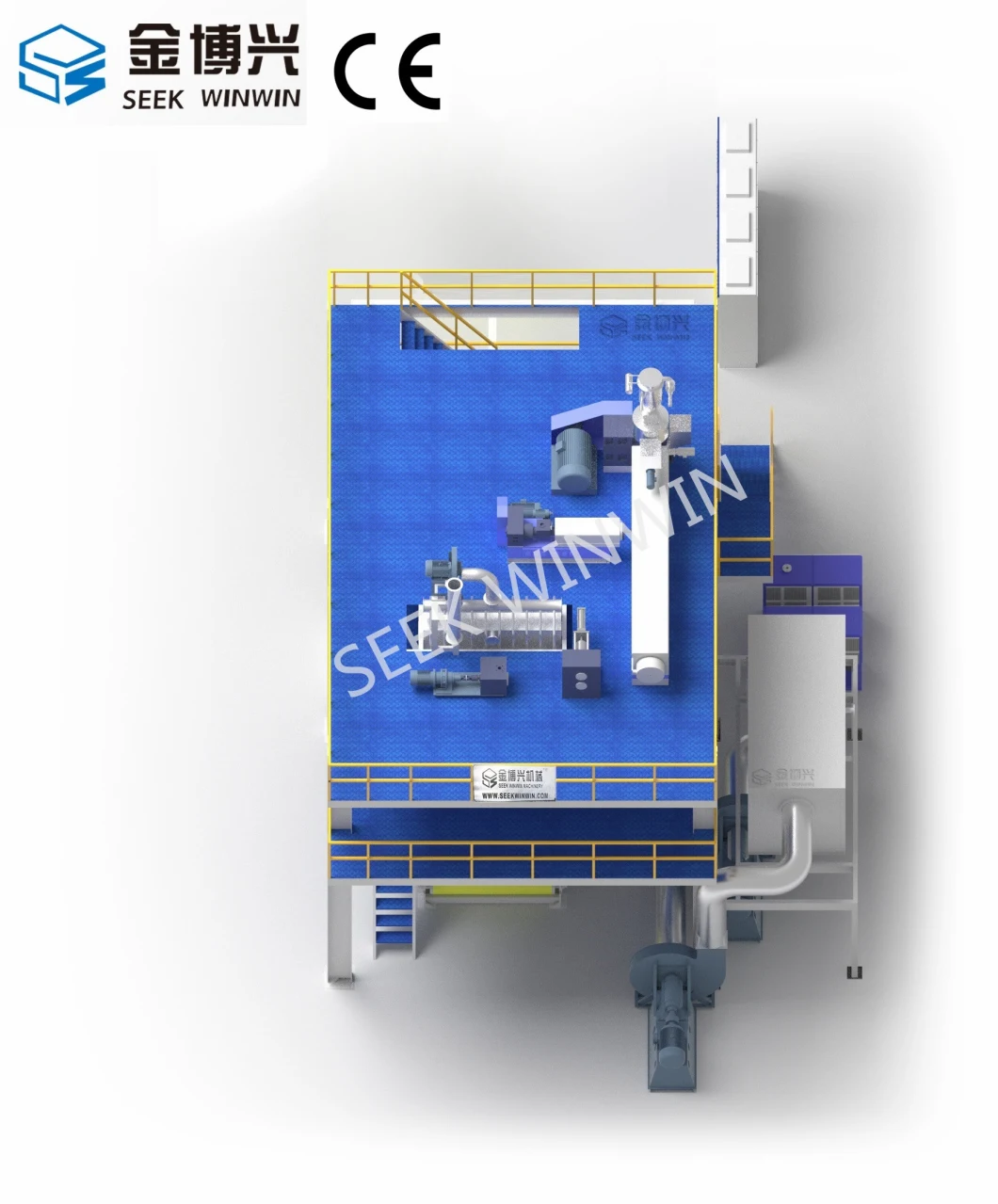

3)The requirement of the workshop and equipment is very simple, it reduces the fixed assets investment, and efficiently take the advantage of the room of the platform, and enlarge the utilization of the workshop and the steel platform.

4)More specialty in processing the main equipment increasing the procession precious and capacity of the machine, this reduces the manufacture cost and to undertake the quality of the product more well

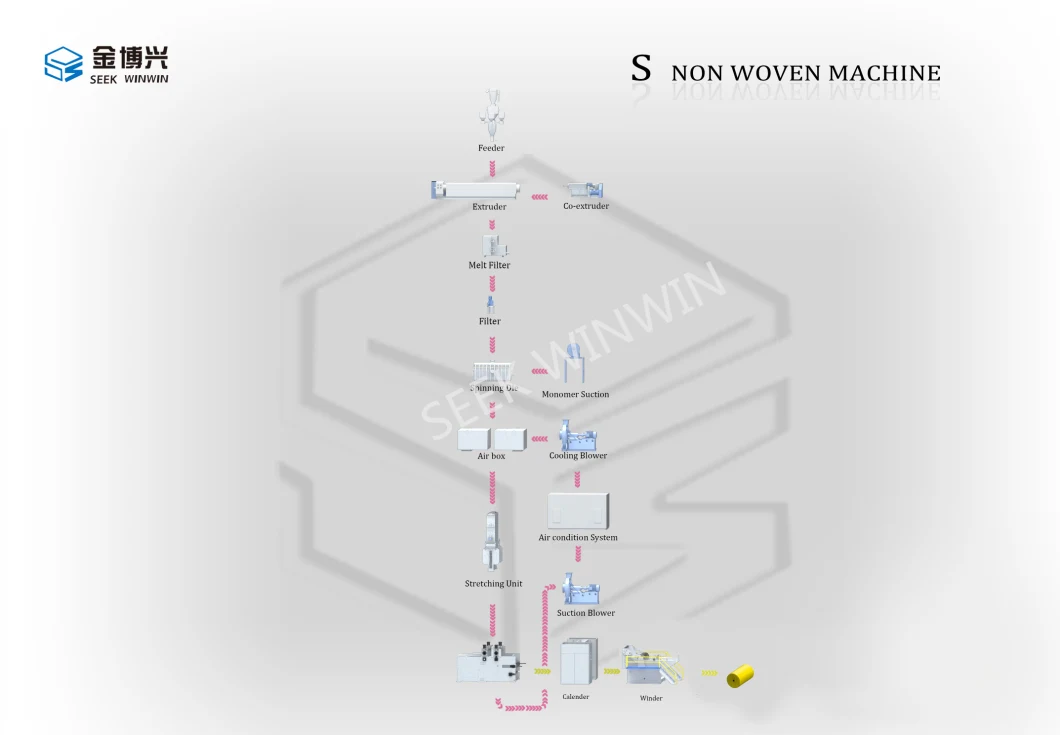

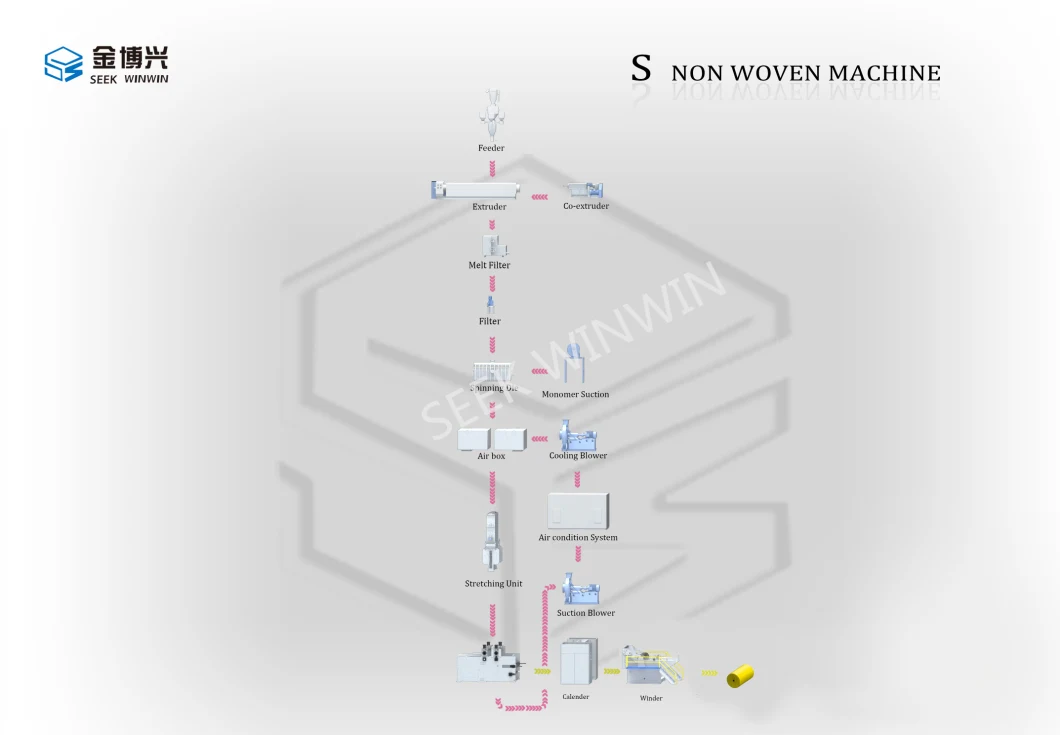

Follow chart of production:

Raw material---- Melting extrusion---Filtering----Measuring---Spinning--Cooling-----stretching----Net making----Heating pressure---winding---slitting----final product Service

Service

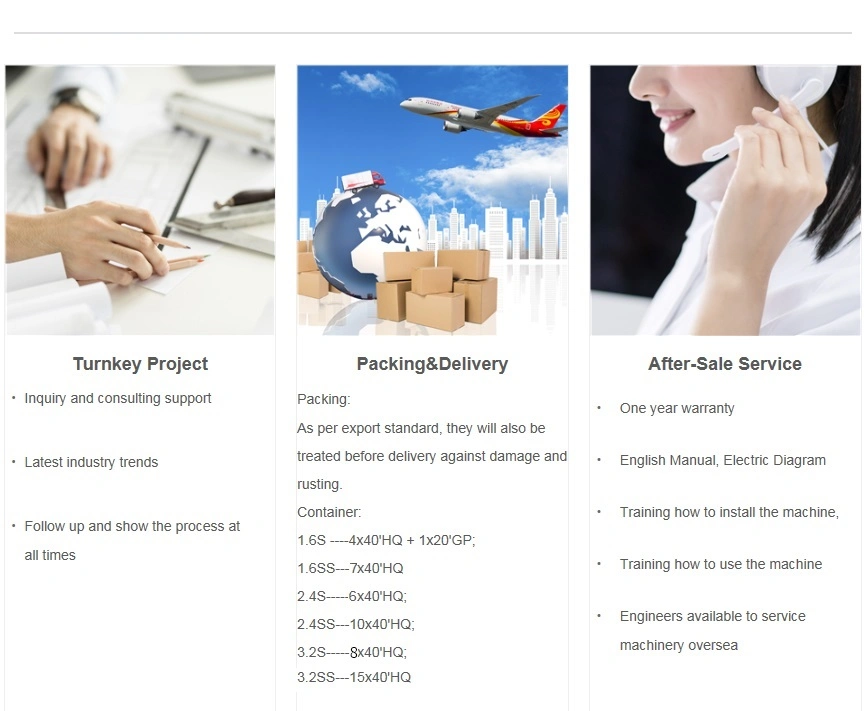

1). Delivery:

We can assemble the line before delivery and invite you come to our factory to inspect the equipment as per your requirement if needed. When you accept the quality of the line, then we will arrange delivery.

2). Training and Installation:

When you receive the whole equipment, we will send 4-5 engineers to your factory for installation and testing. Meanwhile, we will train your workers how to operate the line and normal daily maintenance.

3). After-sales service

In the following year, if you have any problems of the production line, you can send e-mail to us to consult or invite our engineer for service at your site. We will send the professional engineers to help you to solve the problems timely.

The line is to use PP chips as raw materials input, undergoes the Process of extrusion, spinning, quenching, closure air stretching, web Formation, calendering, winding and cutting as per requirements and Then packed for storage and delivery.

1)The lower investment can reduce some unnecessary additional auxiliary facilities, and under the conditions of guaranteeing the technology requirement and safe production, can reduce the cost of the manufacture, so that we can reduce the investment lower.

2)It is easy and reliable to making technics adjustment, the line adopts the method of computer controlling assistant systems combines with human control to make the technics adjustment become more easier and reliable, and the machine can adapt to different raw materials to gain more widely usage.

3)The requirement of the workshop and equipment is very simple, it reduces the fixed assets investment, and efficiently take the advantage of the room of the platform, and enlarge the utilization of the workshop and the steel platform.

4)More specialty in processing the main equipment increasing the procession precious and capacity of the machine, this reduces the manufacture cost and to undertake the quality of the product more well

Follow chart of production:

Raw material---- Melting extrusion---Filtering----Measuring---Spinning--Cooling-----stretching----Net making----Heating pressure---winding---slitting----final product Service

Service

1). Delivery:

We can assemble the line before delivery and invite you come to our factory to inspect the equipment as per your requirement if needed. When you accept the quality of the line, then we will arrange delivery.

2). Training and Installation:

When you receive the whole equipment, we will send 4-5 engineers to your factory for installation and testing. Meanwhile, we will train your workers how to operate the line and normal daily maintenance.

3). After-sales service

In the following year, if you have any problems of the production line, you can send e-mail to us to consult or invite our engineer for service at your site. We will send the professional engineers to help you to solve the problems timely.

PRODUCT SPECIFICATIONS

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN | MACHINE SIZE (LxWxH) |

| S | 1600MM | 10-200 | 1500T | Diamond, oval, cross and line | 15.5x9x10.7m |

| S | 2400MM | 10-200 | 2200T | Diamond, oval, cross and line | 15.5x10x10.7m |

| S | 3200MM | 10-200 | 3000T | Diamond, oval, cross and line | 15.5x11x10.7m |

| SS | 1600MM | 9-150 | 3000T | Diamond, oval, cross and line | 30x12x10.7m |

| SS | 2400MM | 9-150 | 4000T | Diamond, oval, cross and line | 30x13x10.7m |

| SS | 3200MM | 9-150 | 6000T | Diamond, oval, cross and line | 30x14x10.7 |

| SSS | 1600MM | 9-150 | 3500T | Diamond and oval | 33x13x10.7m |

| SSS | 2400MM | 9-150 | 4700T | Diamond and oval | 33x14x10.7m |

| SSS | 3200MM | 9-150 | 7000T | Diamond and oval | 33x15x10.7m |

| M | 1600MM | 20-60 (for mask) | 450T | / | 12x10x6.8m |

| M | 2400MM | 20-60 (for mask) | 660T | / | 12x11x6.8m |

| M | 3200MM | 20-60 (for mask) | 900T | / | 12x12x6.8m |

| SMS | 1600MM | 9-150 | 3100T | Diamond and oval | 32x20x10.7m |

| SMS | 2400MM | 9-150 | 4100T | Diamond and oval | 32x22x10.7m |

| SMS | 3200MM | 9-150 | 6200T | Diamond and oval | 32x24x10.7m |

| SSMS | 1600MM | 9-150 | 3700T | Diamond and oval | 45x20x10.7m |

| SSMS | 2400MM | 9-150 | 4900T | Diamond and oval | 45x22x10.7m |

| SSMS | 3200MM | 9-150 | 7300T | Diamond and oval | 42x24x10.7m |

| SMMS | 1600MM | 13-150 | 3300T | Diamond and oval | 45x20x10.7m |

| SMMS | 2400MM | 13-150 | 4200T | Diamond and oval | 45x22x10.7m |

| SMMS | 3200MM | 13-150 | 6500T | Diamond and oval | 45x24x10.7m |

INDUSTRY APPLICATION

High processed products from PP spunbonded non woven fabric is widely used in medical, household products, agricultural protection, automobile accessories, decorative materials, waterproof materials, shoes, hats, bedding articles, travel products etc.

| Medical and hygienic products: | Operation clothes, disinfect cloth, mask, diaper, beauty products, sanitary towel, pad and other one time health cloth etc. |

| Household products: | Flowers packing cloth, bag fabric, curtain, cover for household, table cloth, sofa cloth, mattress cloth and garderobe cover etc. |

| Daily commodity products: | Over-sleeve, apron, sauna suits, shopping bags, gift bags, store bags, advertisement bags etc. |

| For garments and shoes: | Ski shirt, quilt, work clothes, operation clothes, exposure suit, lining, clothing accessory, garment bag, sweater bag etc. |

| Industrial and agricultural purpose: | Filtering material, insulating material, carpet, car interior decoration cloth, oil absorption material, roadbed cloth, dykes and dams cloth, waterproof rolling fabric, covering cloth etc. |