Product Description

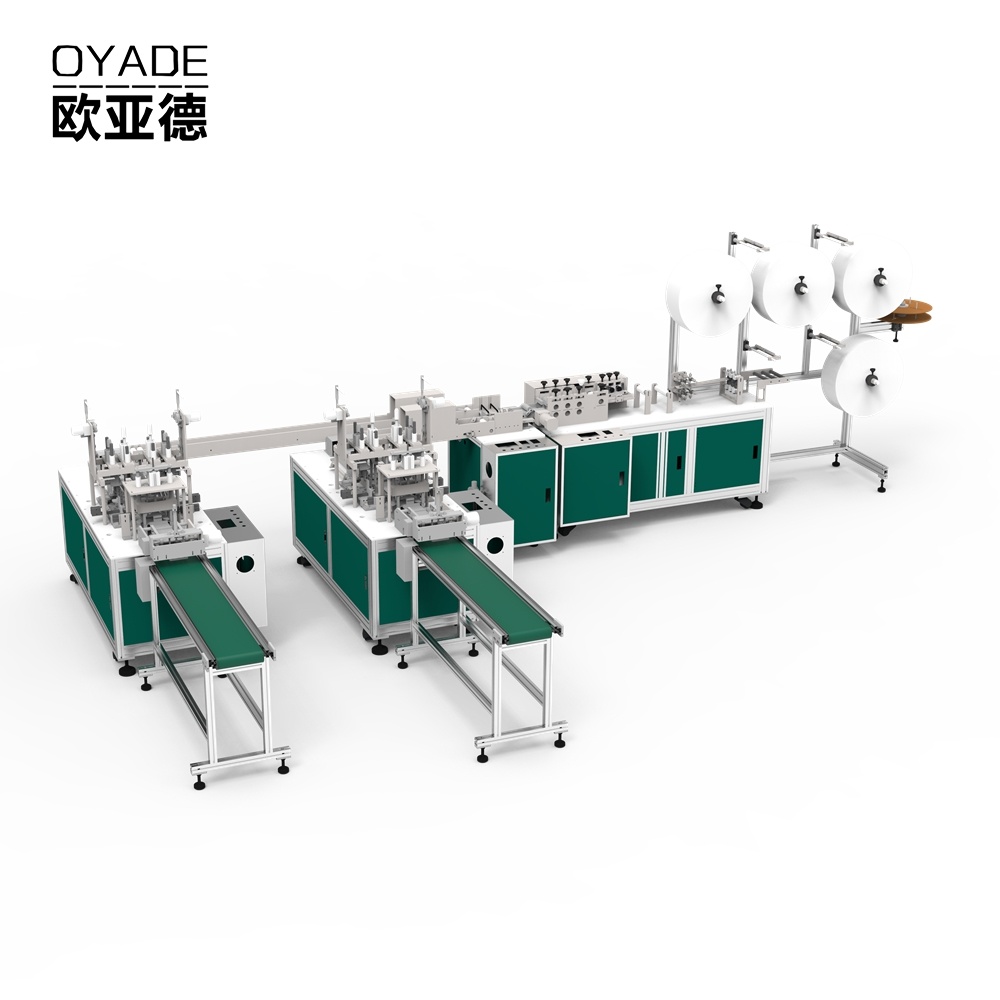

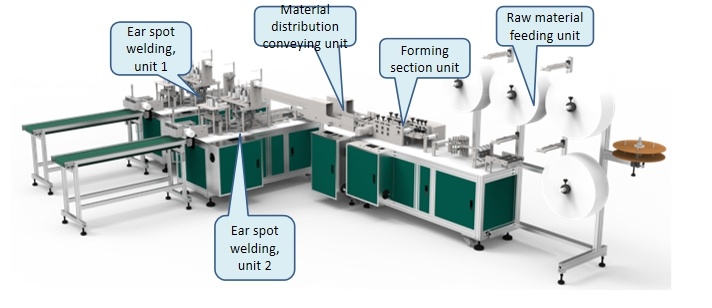

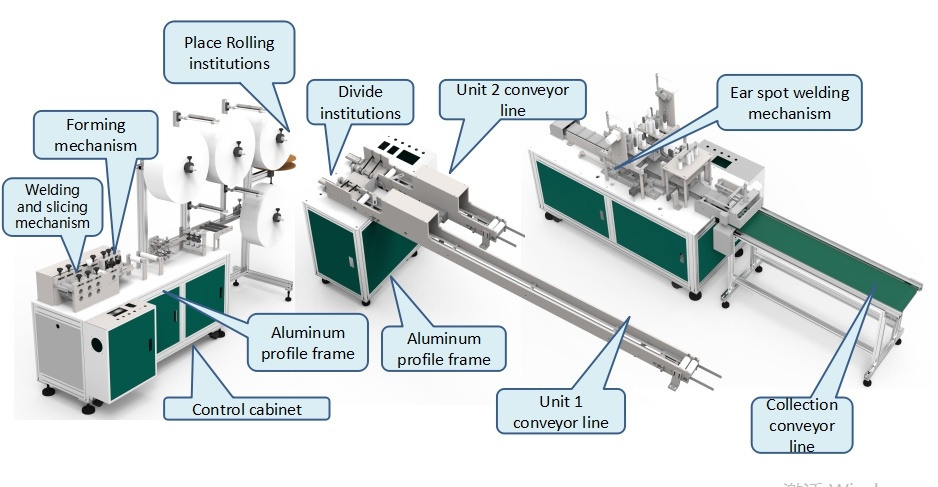

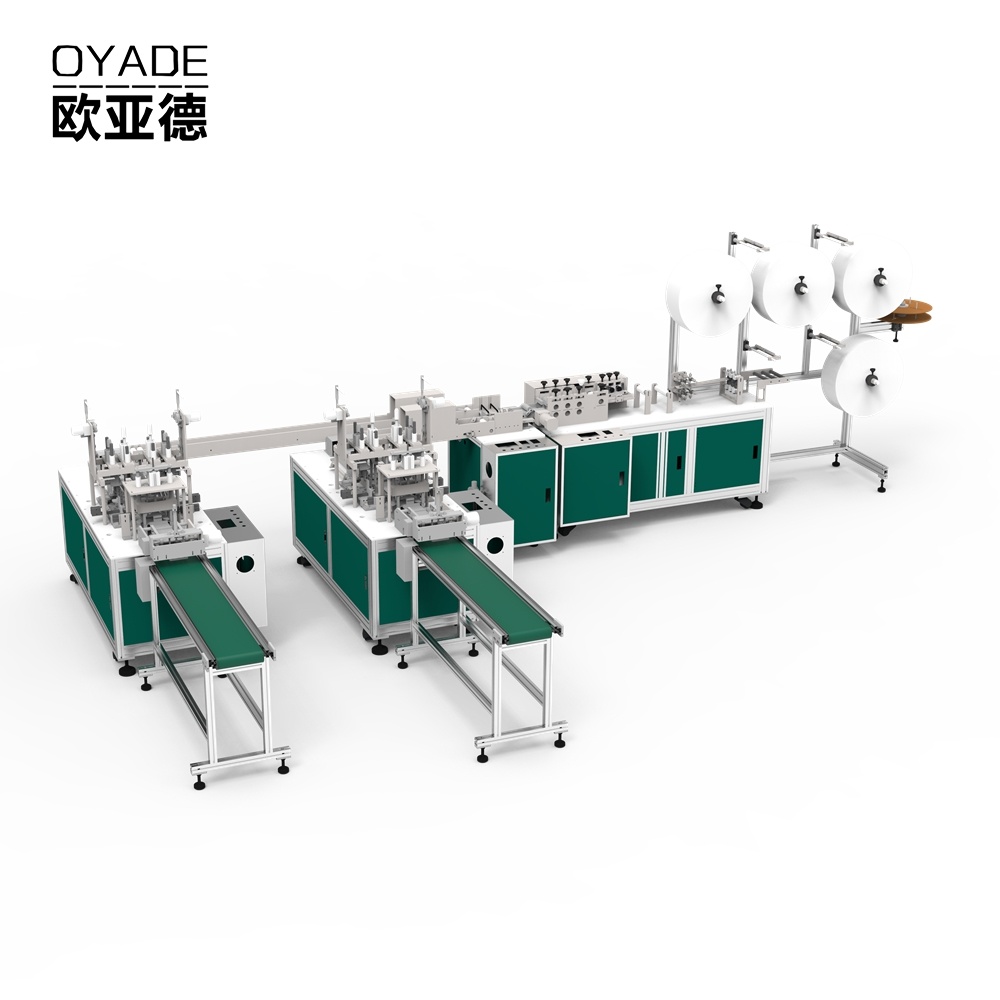

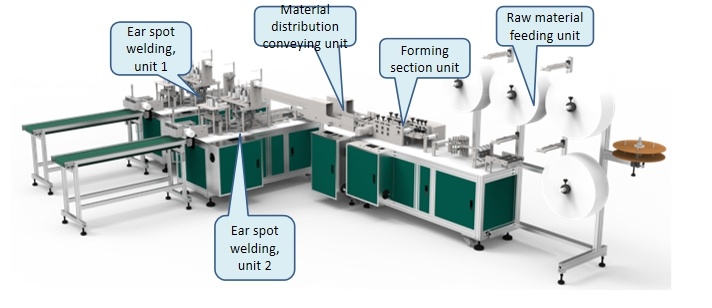

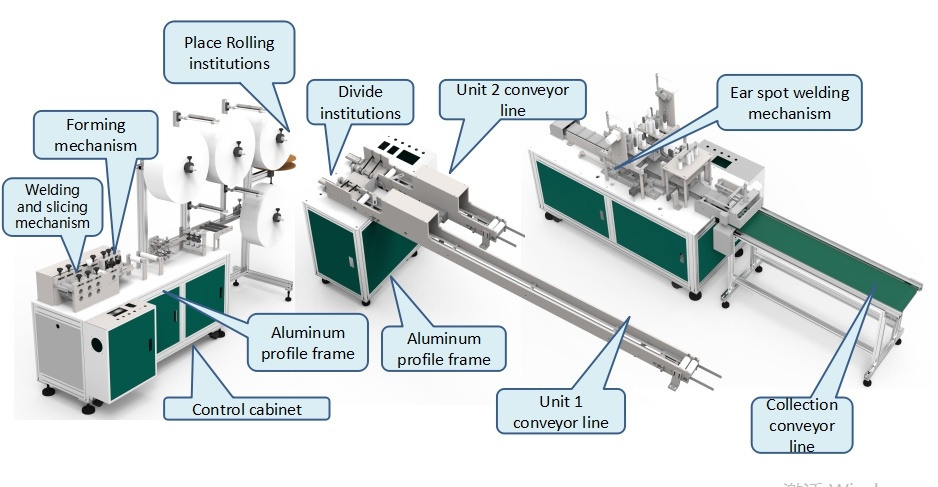

This machine is mainly used for the automatic forming of flat masks: the whole roll of fabric is driven by rollers after unwinding, and the fabric is automatically folded and hemmed; the entire length of the bridge is pulled and unrolled. Ultrasonic welding to the seal, then ultrasonic side sealing, cutting and shaping with a cutter; conveying the mask to the two mask earband welding stations through an assembly line, and finally forming the mask by ultrasonic welding; when the mask is made, The pipeline is transported to the flat belt line for collection.

Our Machine production line Video: https://youtu.be/OkqaoDz5xEQ

Successful commission for our domestic project: https://youtu.be/H5iNFV8GKSE

Our Civil engineer and our workshop: https://youtu.be/fek_NXnebnk

Our Machining equipment video: https://youtu.be/zm5qEs5Ed_c

Function introduction

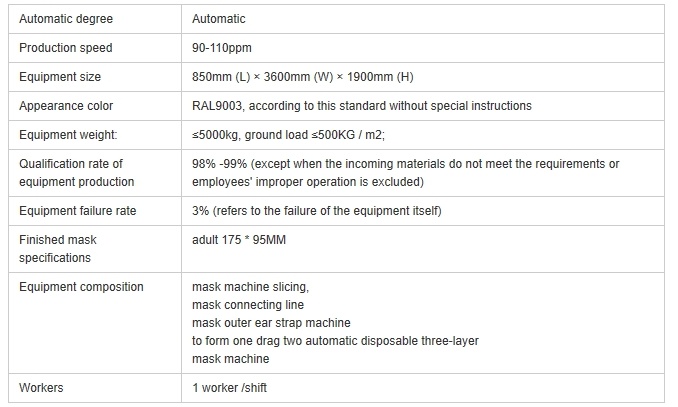

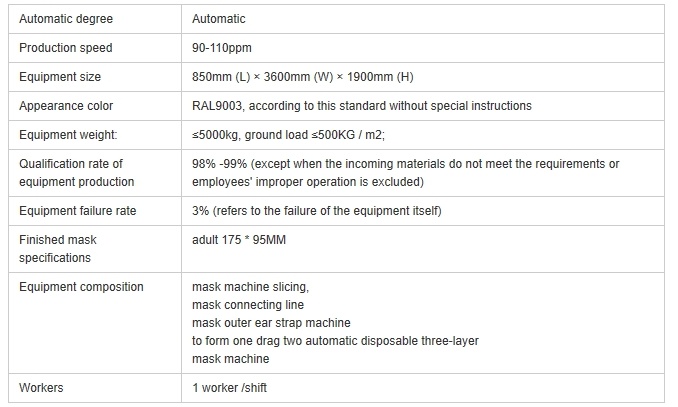

Equipment production capacity:

(1) Production efficiency: 90-110ppm;

(2) Qualification rate of equipment production: 98% -99% (except when the incoming materials do not meet the requirements or employees' improper operation is excluded)

(3) Equipment failure rate: 3% (refers to the failure of the equipment itself)

(4) Equipment staffing: 1 person (1 person can monitor 1 to 3 production lines at the same time)

Specification

Equipment process

Mask machine slicing: unwinding-ultrasonic compound-nasal bridge insertion-precompression compound-folding view-precompression compound-ultrasonic Compound-rolling

Mask connection line: the connection device that automatically transfers the manufactured body mask to the conveyor line of the mask ear band machine Mask connection line: the connection device that automatically transfers the manufactured body mask to the conveyor line of the mask ear band machine

Mask outer ear strap machine: Feed into the body ,Cut tape for size , Raw materials required for ultrasonic welding

Non-woven outer layer (175MM, weight about 25G), PP non-woven composite fiber;

The middle layer is a meltblown cloth (170-200MM, the weight is about 25G);

Non-woven inner layer (190-200MM, weight 25G), PP non-woven composite fiber;

Nose bridge silk plastic strip PP 5.0MM * 0.55MM;

Earband is round with a diameter of 2.5-3MM;

Company introduction

Service

Commission and testing

We have strict quality control system in our company:

Before we delivery machine for you, our engineer will assemble the machine together for you.

And engineers must do debuging and commissioning of machine for you to ensure that machine can be workable well to produce mask successfully in your place.

All these will must be done before loading machine for you.

For us, wearereponsible for customers.

Our Reputation with 12 years is built by our this philosophy.

The final goal for us is not just selling you a machine, but also supporting you to produce the mask in your factory successfully!

Kindly contact Sarah,

I will share you more videoes about our factory and our machine running!!!

This machine is mainly used for the automatic forming of flat masks: the whole roll of fabric is driven by rollers after unwinding, and the fabric is automatically folded and hemmed; the entire length of the bridge is pulled and unrolled. Ultrasonic welding to the seal, then ultrasonic side sealing, cutting and shaping with a cutter; conveying the mask to the two mask earband welding stations through an assembly line, and finally forming the mask by ultrasonic welding; when the mask is made, The pipeline is transported to the flat belt line for collection.

Our Machine production line Video: https://youtu.be/OkqaoDz5xEQ

Successful commission for our domestic project: https://youtu.be/H5iNFV8GKSE

Our Civil engineer and our workshop: https://youtu.be/fek_NXnebnk

Our Machining equipment video: https://youtu.be/zm5qEs5Ed_c

Function introduction

Equipment production capacity:

(1) Production efficiency: 90-110ppm;

(2) Qualification rate of equipment production: 98% -99% (except when the incoming materials do not meet the requirements or employees' improper operation is excluded)

(3) Equipment failure rate: 3% (refers to the failure of the equipment itself)

(4) Equipment staffing: 1 person (1 person can monitor 1 to 3 production lines at the same time)

Specification

Equipment process

Mask machine slicing: unwinding-ultrasonic compound-nasal bridge insertion-precompression compound-folding view-precompression compound-ultrasonic Compound-rolling

Mask connection line: the connection device that automatically transfers the manufactured body mask to the conveyor line of the mask ear band machine Mask connection line: the connection device that automatically transfers the manufactured body mask to the conveyor line of the mask ear band machine

Mask outer ear strap machine: Feed into the body ,Cut tape for size , Raw materials required for ultrasonic welding

Non-woven outer layer (175MM, weight about 25G), PP non-woven composite fiber;

The middle layer is a meltblown cloth (170-200MM, the weight is about 25G);

Non-woven inner layer (190-200MM, weight 25G), PP non-woven composite fiber;

Nose bridge silk plastic strip PP 5.0MM * 0.55MM;

Earband is round with a diameter of 2.5-3MM;

Company introduction

We are Shandong Oyade Machinery, a responsible manufacturer of machines in China since 2008.

With 66000 sqm land and500workers in Jinan city,ShandongProvince.

For12 years'experience in the production of machines, we always put the quality and after-sales service at the top position. Otherwise, our customers will not trust us anymore.

Now we are producing the machine by ourselves exactly. So both for the price and delivery time, we can be ensured for you.

Now what's most important for customers: you can produce the mask with the machine you buy. As every country, the mask is urgent in demand and everyone needs it and it is related to people's health.

So we must ensure that our machine can be operation successfully in your place, if not, we will not give you this machine!!

Service

Commission and testing

We have strict quality control system in our company:

Before we delivery machine for you, our engineer will assemble the machine together for you.

And engineers must do debuging and commissioning of machine for you to ensure that machine can be workable well to produce mask successfully in your place.

All these will must be done before loading machine for you.

For us, wearereponsible for customers.

Our Reputation with 12 years is built by our this philosophy.

The final goal for us is not just selling you a machine, but also supporting you to produce the mask in your factory successfully!

Kindly contact Sarah,

I will share you more videoes about our factory and our machine running!!!