Micro duct assembly & sheating pipe making machine is tailored according to the inner duct numbers. High efficient extruder equipped for extruding the outer sheating layer. Our extruder is with own-patented screw and barrel, which can not only improve the extruding capacity, but also saving power. Currently, our machine's power consumption is 20-30% lower than similar machine.

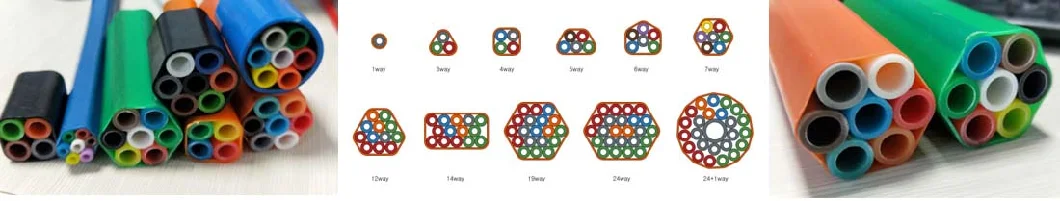

Duct bundles sheating type:

| No | Inner duct OD(mm) | sheating type | |||

| DB | DI | FLAT | LINK | ||

| 1 | 5mm | 1--24+1way | |||

| 2 | 7mm | 1--24+1way | 2-7way | 2-9way | |

| 3 | 8mm | 1-12way | |||

| 4 | 10mm | 1-7way | 7way | 2-7way | 2-7way |

| 5 | 12mm | 1-7way | 7way | 2-7way | 2-7way |

| 6 | 14mm | 1-7way | 2-7way | 2-7way | |

| 7 | 16mm | 1-7way | 2-7way | 2-7way | |

| 8 | 18mm | 1-7way | 2-7way | 2-7way | |

| 9 | 20mm | 1-7way | 2-7way | 2-7way | |

HDPE microduct bundles extrusion line including:

| No. | Machine Set Composition |

| 1 | Duct PE Pipe Uncoiler |

| 2 | High Efficient PE Pipe Extruder |

| 3 | Micro Duct Bundles Shaping Device |

| 4 | PE Jacket Pipe Cross Type Design Die Head |

| 5 | Cooling Tank |

| 6 | Haul-off Machine |

| 7 | Gantry Type Pipe Coiler |

| 8 | Siemens PLC Computer Control System |

Features of the Micro-duct bundles extrusion line:

1)Specially designed die head moulds according to the numbers of tube bundles.

2) Reasonable uncoiler layout according to numbers of tube bundles .

3) Stable performance haul-off machine,equipped with 8 air cylinder.