1600mm meltblown machine medical mask melt blown machine air compressor

Description of melt blown nonwoven fabric making machine

melt blown machine is the most core material of mask, melt spraying cloth mainly USES polypropylene as the main material, the fiber diameter can reach 1 ~ 5 micron.The microfiber with unique capillary structure increases the number and surface area of fiber per unit area, so that the melt spray cloth has good filtering, shielding, insulation and oil absorption.Can be used for air, liquid filtration materials, isolation materials, absorption materials, mask materials, warm materials, oil absorption materials and wiping cloth and other fields.

Working principle of melt blown nonwoven fabric making machine

Polypropylene PP material through the feeding machine into a single screw extruder to squeeze out the polymer melt, through high-speed hot air or other means, the polymer by extreme stretch and form very fine short fiber, and agglomerate on the porous formation of fiber network, and finally through its own bonding and strengthening to form non-woven fabric, finally produce melt spray cloth.

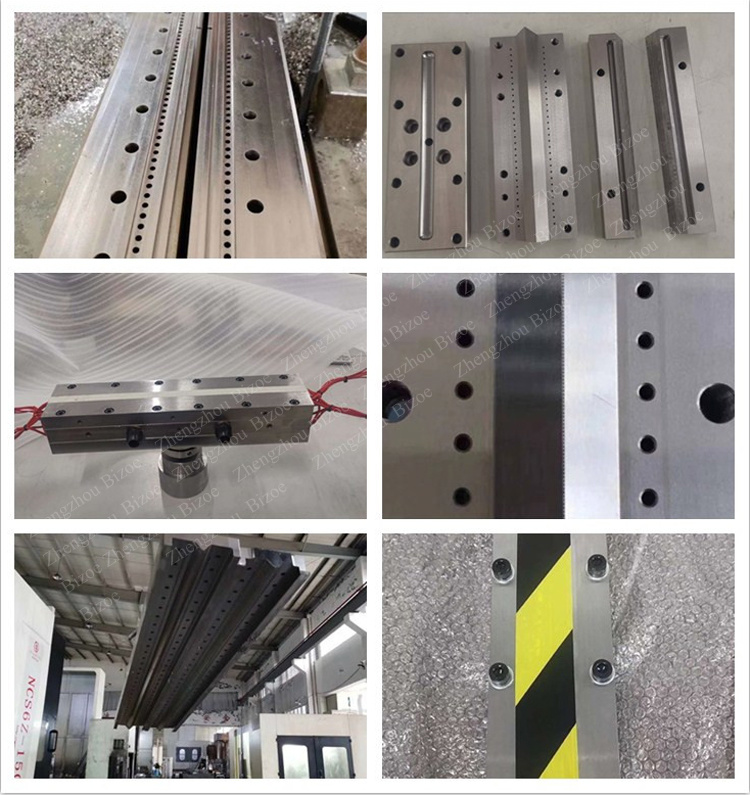

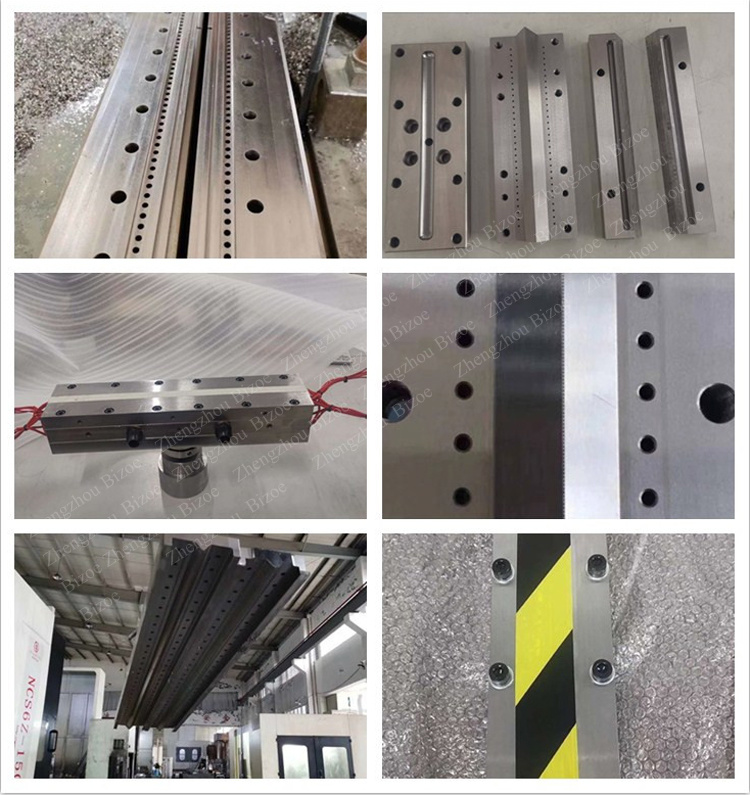

Mold picture of melt blown nonwoven fabric making machine

Product parameter of melt blown nonwoven fabric making machine

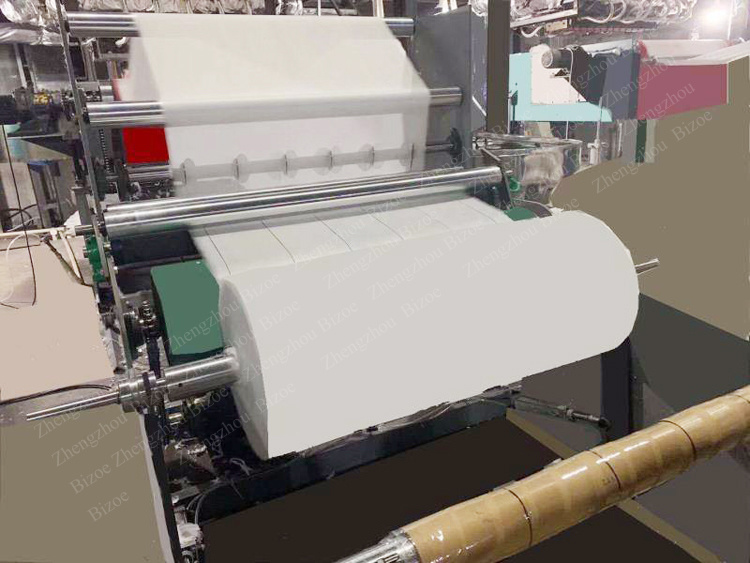

Main product of melt blown nonwoven fabric making machine

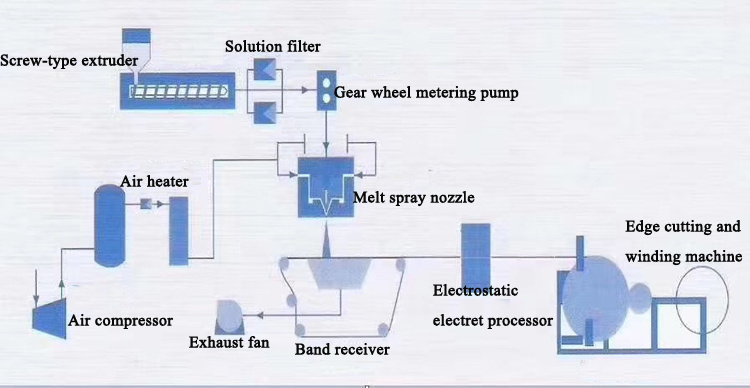

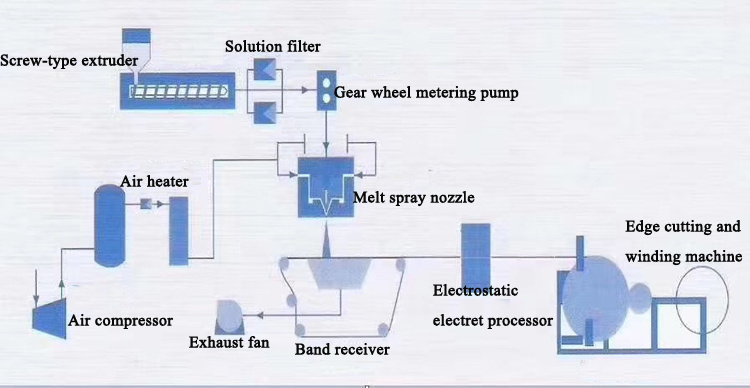

Product process of melt blown nonwoven fabric making machine

Fusion-sprayed fabric is a polymer melt extruded from the nozzle hole of die head by using high-speed hot air flow to draft the thin flow, so as to form a microfiber and collect it on the condensation screen or roller, at the same time, its own adhesion and become a fusion-sprayed nonwoven fabric. The production process of melt spraying cloth is mainly as follows:

Product packaging and shipping

Company profile

Description of melt blown nonwoven fabric making machine

melt blown machine is the most core material of mask, melt spraying cloth mainly USES polypropylene as the main material, the fiber diameter can reach 1 ~ 5 micron.The microfiber with unique capillary structure increases the number and surface area of fiber per unit area, so that the melt spray cloth has good filtering, shielding, insulation and oil absorption.Can be used for air, liquid filtration materials, isolation materials, absorption materials, mask materials, warm materials, oil absorption materials and wiping cloth and other fields.

Working principle of melt blown nonwoven fabric making machine

Polypropylene PP material through the feeding machine into a single screw extruder to squeeze out the polymer melt, through high-speed hot air or other means, the polymer by extreme stretch and form very fine short fiber, and agglomerate on the porous formation of fiber network, and finally through its own bonding and strengthening to form non-woven fabric, finally produce melt spray cloth.

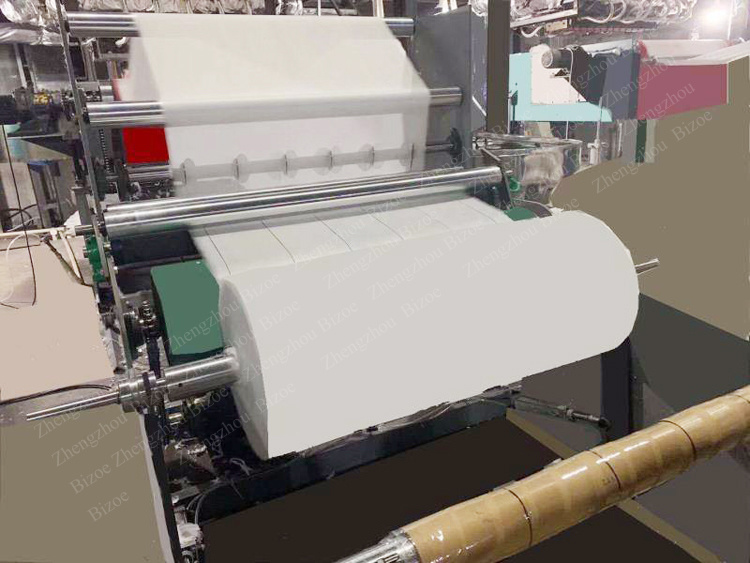

Mold picture of melt blown nonwoven fabric making machine

Product parameter of melt blown nonwoven fabric making machine

| 1.Product width | 600mm | 3x175mm(melt blown cloth width is 600mm) | 1225m | ||

| 2. Production capacity | 400-500 kg/day(24hours working hours per day) | 500kg/day(24hours working hours per day) | 1300 kg/day(24hours working hours per day) | ||

| 3. Main raw material | polypropylene chips/granules,high melt index MFR 1500g/10min | ||||

| 4. Fiber fineness | average 2-5um | ||||

| 5. Product basis weight | 18-80g/m2(disposable mask is 25gsm-30gsm) | ||||

| 6. Production speed | <=30m/min | ||||

Product process of melt blown nonwoven fabric making machine

Fusion-sprayed fabric is a polymer melt extruded from the nozzle hole of die head by using high-speed hot air flow to draft the thin flow, so as to form a microfiber and collect it on the condensation screen or roller, at the same time, its own adhesion and become a fusion-sprayed nonwoven fabric. The production process of melt spraying cloth is mainly as follows:

1. Melt preparation

2. Filtration

2. Filtration

3. The measurement

4. The melt is extruded from the spinneret

5. Melt fine draft and cooling

6. Into the net

Product packaging and shipping

Company profile